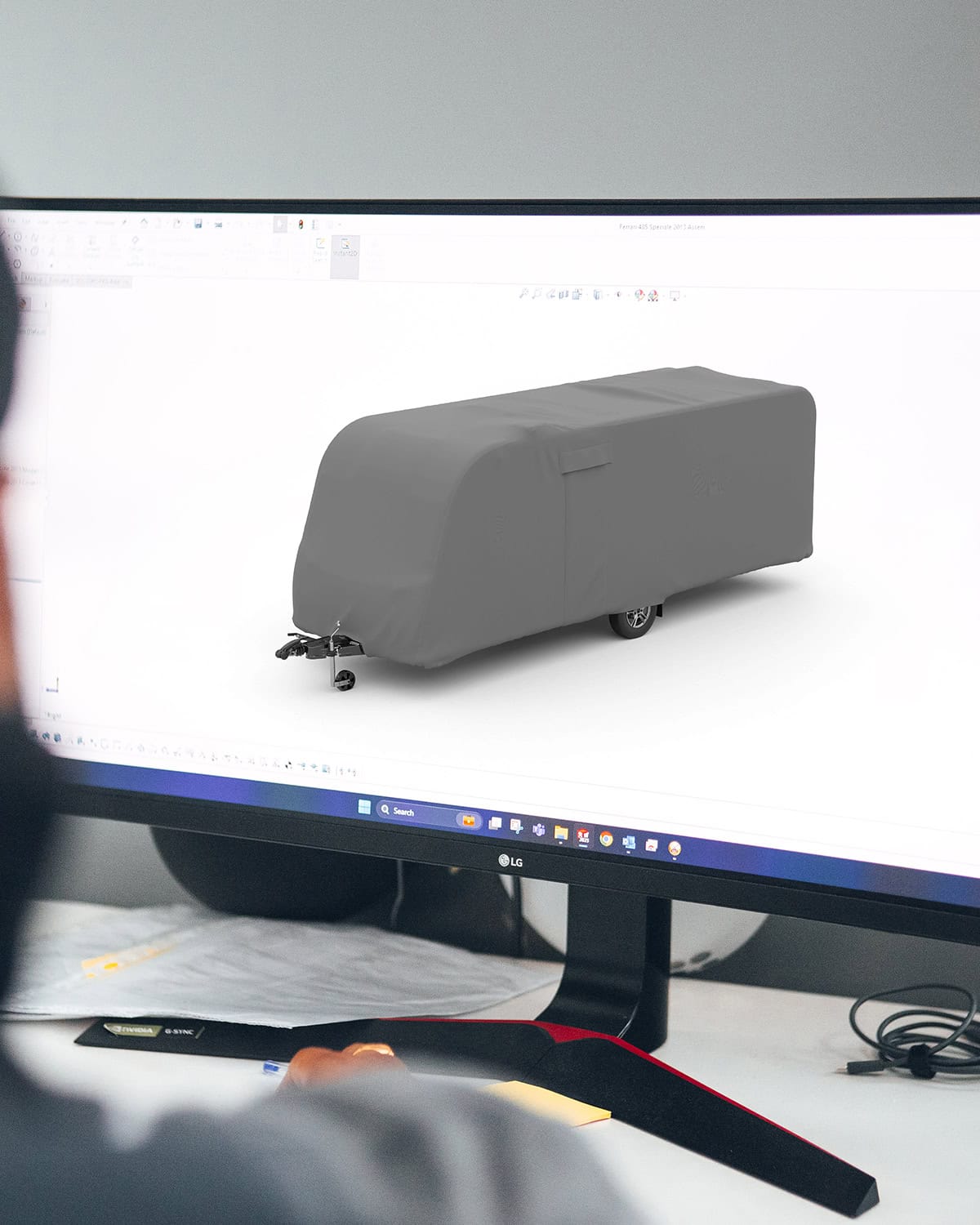

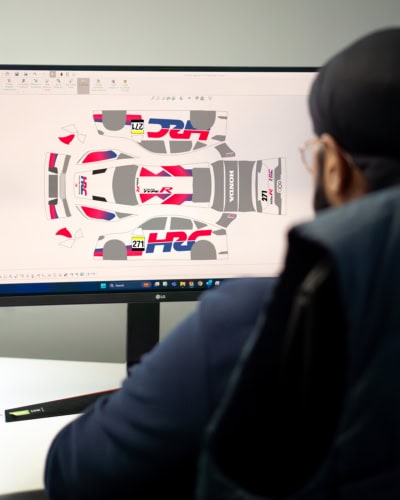

Bespoke Tailoring Service guide cost £499

The ultimate in tailoring, two of our designers will travel to your location to measure and create the pattern for the vehicle, caravan, or kitchen using cloth patterning methods as in Savile Row suits, alternatively we can also Proliner the vehicle to create a 3D scan. The team can discuss with you onsite design options and fabric requirements ensuring you receive the perfect protective cover.